XL Series

We’ve got you covered

The XL Series viscometer range covers everything. Every fluid. Every application. With mind-blowing performance, around the clock, around the globe. We’re always there. The most noisy, hot, cold, fast, hygienic, aggressive, hazardous, or extreme environment you can imagine. From high temperatures and pressures, to open tanks and troughs. There’s a Hydramotion for you.Standard > | High Temperature > | Long Reach > | Special Ops >

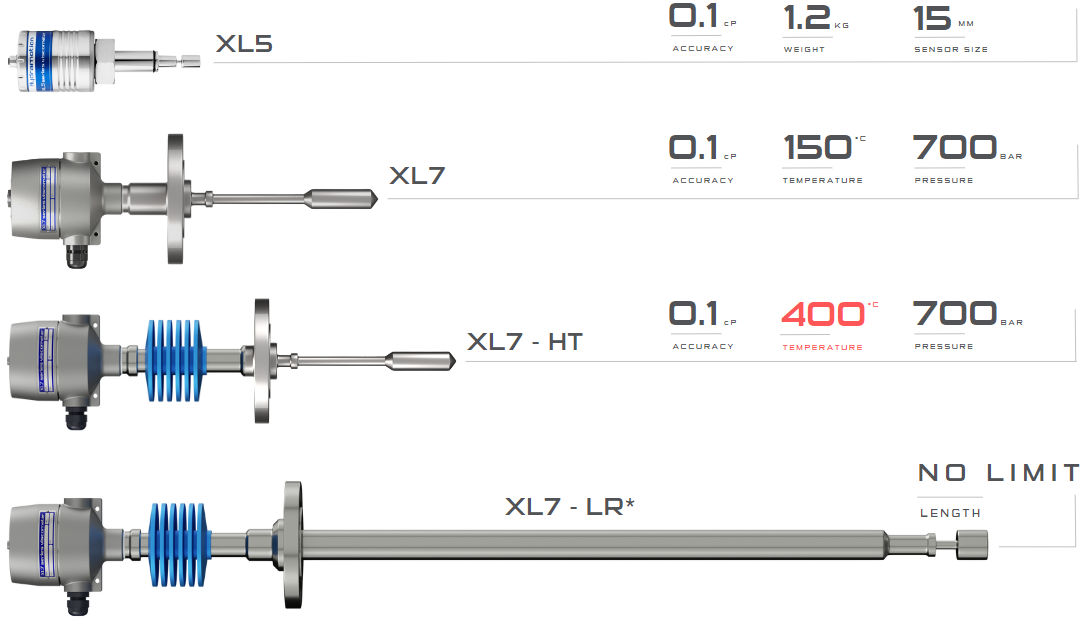

XL3Ultra-compact, ultra-lightweightCore performance in an ultra-small package. Standalone and ready to deploy Discover XL3 > |

XL5Compact and lightweightSmall scale. Zero compromise. High performance with a reduced footprint Discover XL5 > |

XL7The ultimate powerhouseFull spec and fully configurable. The industry standard process viscometer Discover XL7 > |

Spec Ops*Pushing the boundariesBespoke design service. Any shape, any size, any spec. Tailored to you Discover Spec Ops > |

Key Features

SMART SOLUTIONS FOR INDUSTRY

Every viscometer is engineered to deliver reliable, repeatable performance in demanding environments, providing practical solutions to critical process measurement problems across a broad range of applications.

Operating Principle

- The solid stainless steel sensor element is submerged in the fluid and made to move back and forth microscopically at a specific frequency

- As the surface of the sensor shears through the liquid, energy is lost to the fluid due to its viscosity

- The dissipated energy is accurately measured by Hydramotion’s microprocessor-controlled electronics and equated back to viscosity

- Higher viscosity causes a greater loss of energy and hence a higher reading

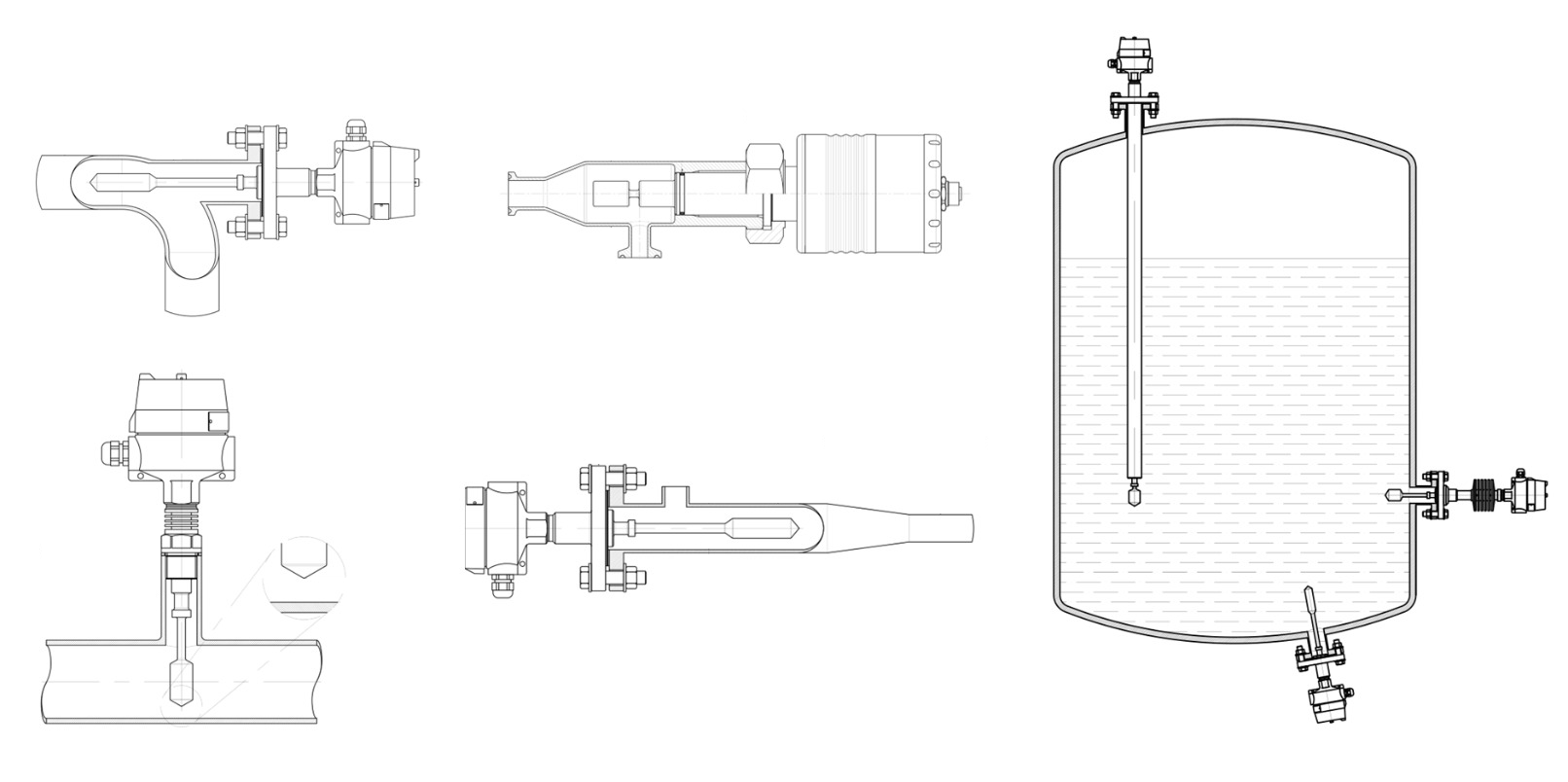

Installations

Installation Options

| Tank Mounted | Pipe Elbow Mounted | Pipe Tee Mounted |

|---|---|---|

| Install in any orientation. In a tank or vessel of any size. All that is required is a suitable mating process fitting. And where there’s limited availability, we will design something custom to fit | For optimal elbow installation mount transducer in a pipe bend and pointing into the heart of the flow. Any pipe size. Any flow rate | Tee mounted option for large bore pipes to reach the middle of the flow. And a reducing tee option for a high integrity mechanical connection |

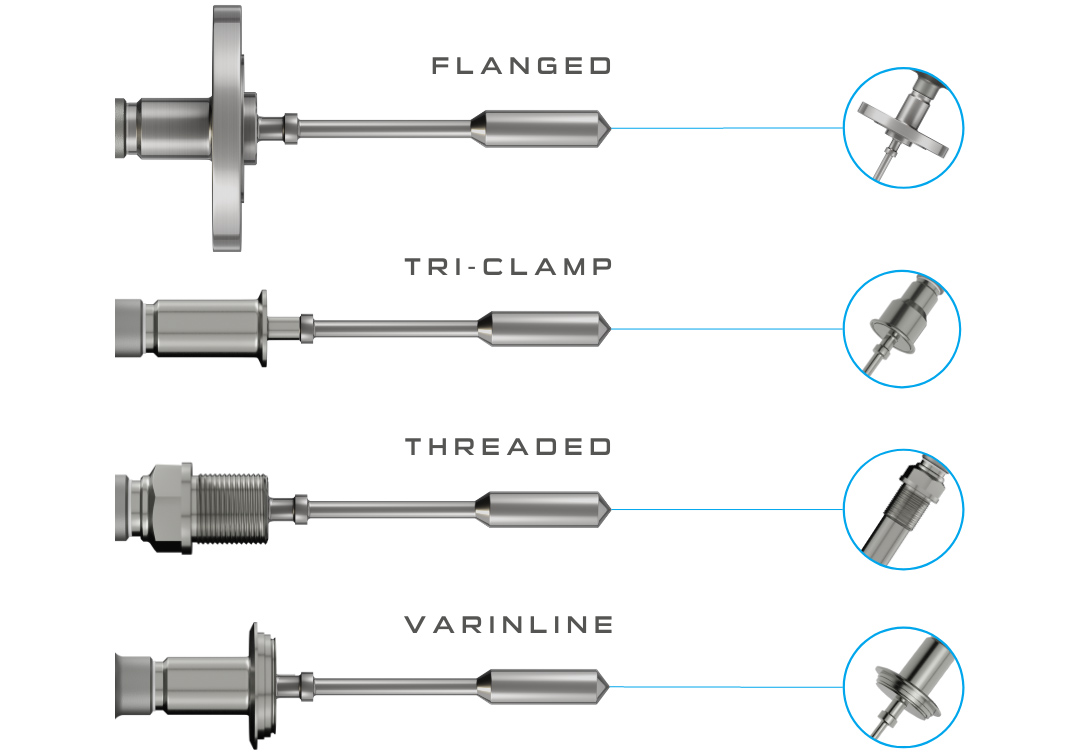

Any Process Connection

| Flanged | Hygienic | Threaded |

|---|---|---|

| All shapes and sizes available. Standards include: ASME, DIN, BS10, JIS/KS and others |

Any size or type of sanitary fitting. Triclamp, RJT, IDF, DIN, SMS, Varinline® and others | All common thread types available. NPT, NPS, BSPP, BSPT, UN/JIC/SAE, Metric and others |

Special Ops

Our Engineer To Order division routinely deals with many complex design objectives. Working with your existing plant layout, our engineers use their knowledge and expertise to create a perfect fit – anything from a slight alteration to an extension of several metres. We have a huge legacy of experience to draw on and can cope with just about anything.Inactive shaft extensions means we can accommodate varying nozzle lengths and sizes. And custom sensor geometries means we can design an instrument to your exact viscosity range, sensitivity, and process specifications whilst maximising performance.

Take the next step…

Connectivity

VP550 |

VP250 |

|---|---|

| The VP550 Processor provides all the functions needed to get the best out of your inline viscosity meter. Critical viscosity data and sensor management are available at the touch of a button. | A compact, rail-mounted mini-processor that connects to Hydramotion viscosity sensors. Acts as an intelligent terminal block with a miniature display and useful analogue and digital outputs. |

| Learn More > | Learn More > |

EX CERTIFIED

Every XL Series viscometer is available as an Ex Certified product and is certified using the Intrinsic Safety (IS) protection method.IS certification permits a simpler installation than flameproof. The Ex ‘ia’ certificate allows transducers to be operated even in the most hazardous Zone 0 environments.

A HOME FROM HOME

We don’t believe in expensive service contracts or regular downtime. Our instruments are built to last. And every viscometer comes with the Hydramotion seal of approval.

All this is supported by our After Sales team who ensure that our track record as successful partners in shared challenges is maintained. Every viscometer purchase grants you access to our world class support backed up by over 30 years industrial experience solving the most complex problems in the viscosity measurement world. It’s a service we hope you’ll never need, but we’re always here. Your home from home.

Industries

| Auto & Aerospace | Bio-fuels & Renewables | Chemicals |

|---|---|---|

| Hydramotion viscometers are used widely in manufacture, maintenance and operational applications in transport technologies for coatings, adhesives, lubricants and fuels… Explore > |

The viscosity of fuels affects their ignition temperature, heat of combustion, the rate at which they burn, density, melting points, energy density and lubricity… Explore > |

Measuring viscosity is critical during mixing, blending, and detecting the reaction end-point, which is often the key to reducing waste and eliminating batch failures… Explore > |

| Coatings | Combustion & Power | Cosmetics |

|---|---|---|

| The repeatability and reproducibility of the coating process is closely linked to the coating’s viscosity, and is therefore a key parameter to control. Dip-in, tank based or in-line sensors… Explore > |

Higher viscosity fuels have poorer combustion efficiency. Viscosity influences the degree of preheating required for handling, storage and satisfactory atomization… Explore > |

Even with an irresistible fragrance and clever placement in the market, a cosmetic product will only be received favourably by consumers if it has a pleasant consistency… Explore > |

| Food & Beverage | Inks & Dyes | Mineral Processing |

|---|---|---|

| Viscosity is critical during the food production process to control flowability, waste product and product quality, in order to maximize production efficiency and cost… Explore > |

Viscosity has a direct influence on final print results and quality. Controlling the viscosity of inks and dyes is a major factor in managing costs and maintaining quality… Explore > |

Hydramotion viscosity meters are found at that heart of many mineral processes: pumping and transport, grinding, flotation, mixing/leaching, and thickening… Explore > |

| Oil & Gas | Pharmaceuticals | Polymers |

|---|---|---|

| Hydramotion viscosity meters are used widely for the measurement of crude oil and all its refined fractions, either as part of the refinement processes or end products… Explore > |

Whether it is small samples, reaction vessels, or large volume processing, Hydramotion viscometers measure viscosity at the heart of the fluid as the reaction progresses… Explore > |

There is a Hydramotion in-line viscosity meter for every stage of polymer processing and handling: material manufacture, melt pipe transportation, or extruder… Explore > |

| Pulp & Paper | Resins | Waste & Water |

|---|---|---|

| The amount of starch has an impact on paper strength, printability and other qualities and can be controlled in real time since solids concentration is precisely related to viscosity… Explore > |

Measuring the viscosity of resin in the process is absolutely critical to its outcome: it is a powerful reaction indicator at either the manufacture, storage or use stages… Explore > |

Viscosity is important for the manufacture and use of polymers for water treatment. Polymer chain lengths directly influence viscosity, as does polymer dilution and crosslinking… Explore > |