ViscoMelt

Viscosity, MFI and IV are the decisive

flow properties of polymer melts.

ViscoMelt™ gives you all 3. In real time. With no fuss.

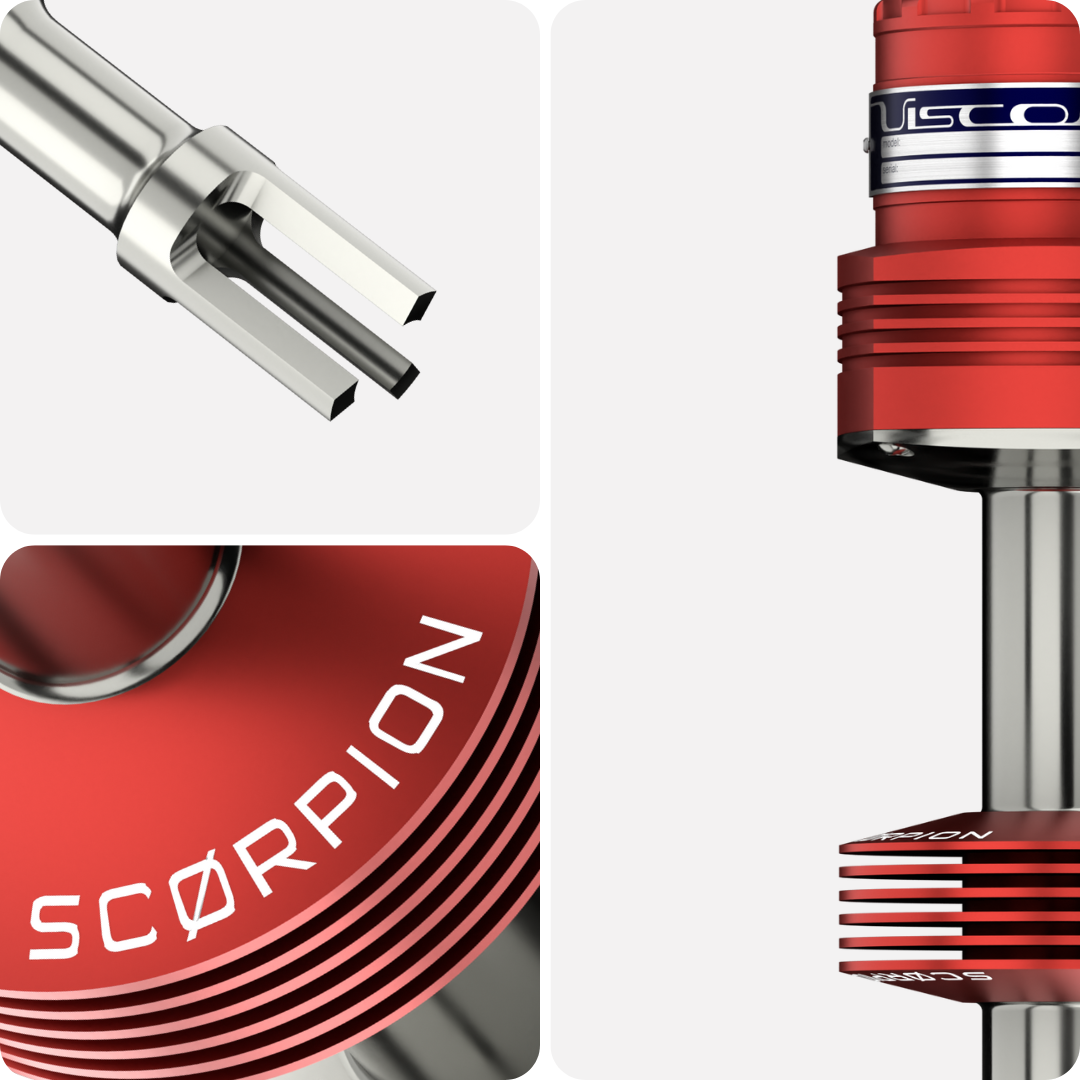

ViscoMelt is a family of highly-resilient inline viscometers which provide critical melt flow data every few seconds with exceptional repeatability. Powered by Scorpion melt flow technology, the inconel-tipped spike architecture are built to withstand the extreme process conditions of high temperature, pressure, and viscosity.

Real time melt data

At your fingertips

One simple device does it all.

Viscosity. MFI. IV. Instant insights, anywhere you need them. Tablet, phone, or integrated system. Stay in control with real-time melt stream analysis.

No sampling. No offline measurements No labour costs.

.png?)

The control you need.

Where you need it.

.png?)

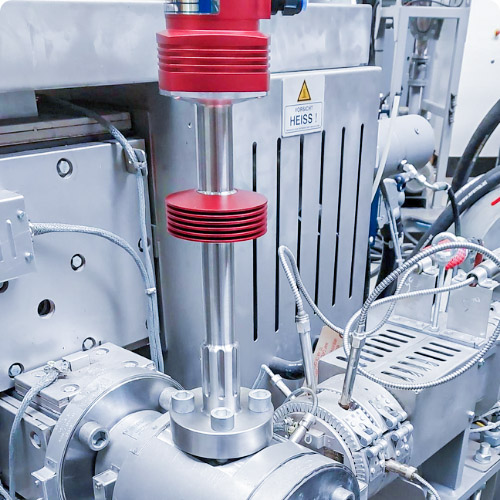

Extruder

Compact and lightweight. |

Melt Pipe

Sits in the heart of the flow. |

Tank

Reach deep into the tank. |

Why Choose

ViscoMelt?

Affordable: fraction of the cost of capillary systems

No maintenance: negligible cost of ownership

Fast: real time viscosity every 5 secs – 99% faster than lab

Deploy anywhere: forget site disruption and costly installation

The all-in-one solution: viscosity, MFI, IV and temperature

Compact. Lightweight. And simple to install.

.png?)

3 Daily Profit Drivers

Increase QualityAchieve end-product quality by detecting raw material variability in real-time and proactively take action. |

Eliminate WasteSlash defect and scrap rate by instantly detecting off-spec product. Adjust the process in real-time to bring the material back into spec. |

Transform ProductivityAutomate your polymer measurement and control. Reduce reliance on manual offline measurements. |

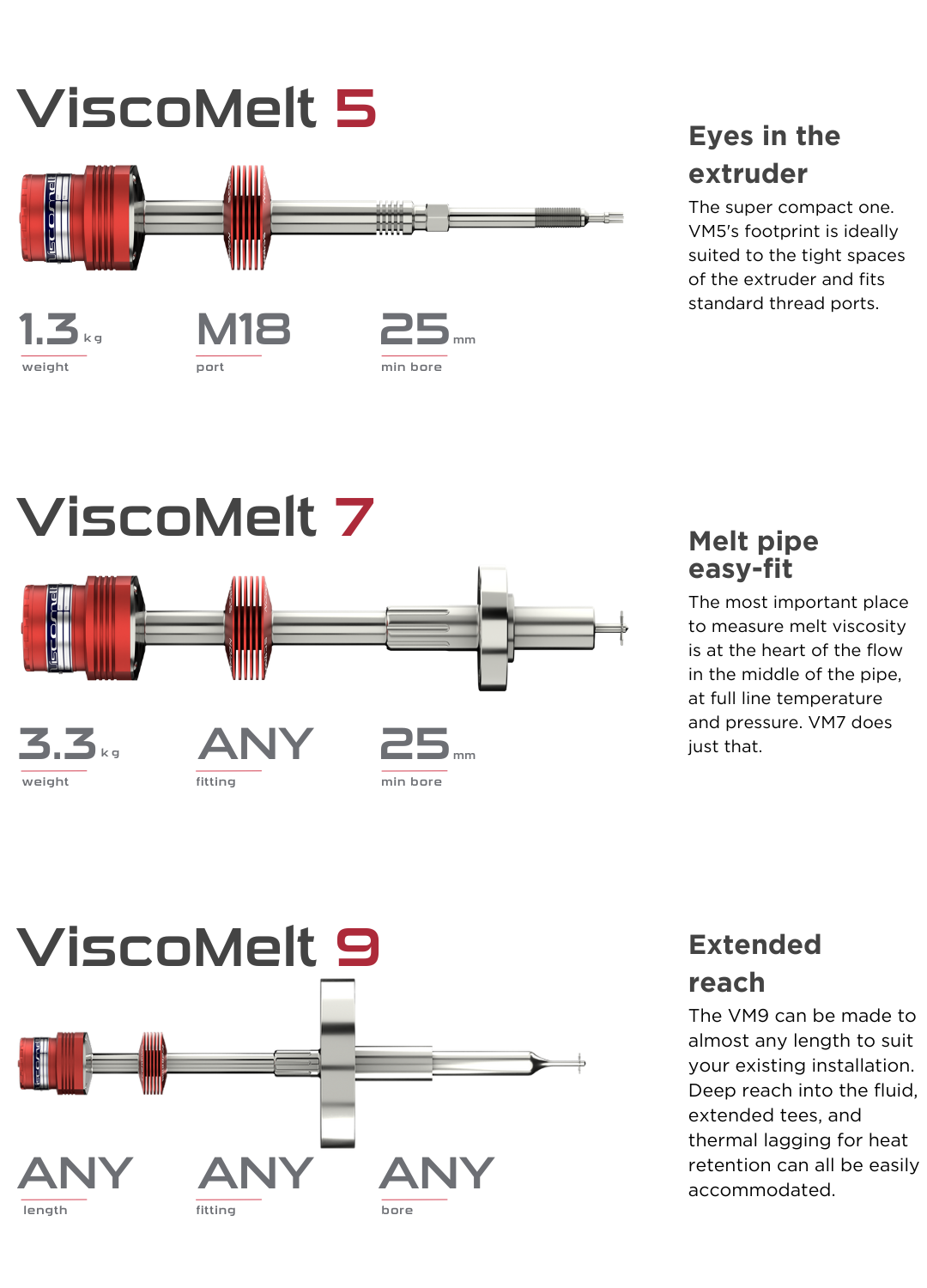

Meet the viscomelt™ family

Powered by Scørpion™ technology

Download Product Brochure

Designed to Retrofit

Upgrade a thermometer to a melt viscometer. It’s that easy.The small VM5 footprint is ideally suited to narrow bore entry ports and is designed to easily replace other melt sensors.

ONE SOLUTION

FOR THE WHOLE POLYMER JOURNEY

PP | HDPE | LDPE | LLDPE | PET | PS | ABS | PA6 | PA66 | EVA | TPE | PC

ViscoMelt works right across the value chain delivering melt flow data for all thermoplastic resins, across every stage of production, manufacture and reuse.

Its all about Scørpion

Instant polymer analysis

ViscoMelt is powered by Scorpion. A next-generation melt flow sensor technology designed for the demands of modern polymer processing. The inconel monopole spikes sit directly in heart of the flow. Their compact design allows melts to flow freely over the sensor surface, with an instantaneous response upon fluid contact.

Making Waves

How Scørpion Works

| The stainless steel alloy base resonator with its Scorpion tip is immersed in the flow of the polymer melt at full process operating temperature and pressure.

The Scorpion spike radiators at the tip are made to microscopically propagate radial waves into the polymer melt. | Radial propagation is strongly and predictably influenced by both polymer viscosity and elasticity which then alters the harmonic behaviour of the base resonator.

Viscosity and elasticity are simultaneously measured by head electronics and related directly to molecular weight, melt flow index and intrinsic viscosity (IV). |

Learn more about Scørpion™ technology

When we say fast.

We mean it

All traditional techniques require extraction of the polymer for testing. This means sluggish results that often don’t represent the whole polymer.

Everythings different with ViscoMelt. Mounted at the centre of the flow, the melt passes freely over the Scorpion monopoles, detecting changes in the whole polymer stream instantly. Full visability at the heart of the melt, in seconds.

.png?)

Know your polymer

ViscoMelt can identify different polymer grades in real time and enable an immediate response to spec deviations. This helps minimise product defects and boost throughput. Tracking melt viscosity also allows on-the-fly adjustments to meet specific end-product requirements.

For recycling processes ViscoMelt facilitates better blending of recycled and virgin materials by providing a true picture of melt behaviour under real processing conditions. As a critical quality parameter, accurate IV monitoring is essential for ensuring product stability and downstream operations.

Be the first to know whats happening to your polymer.

Knowledge is power.

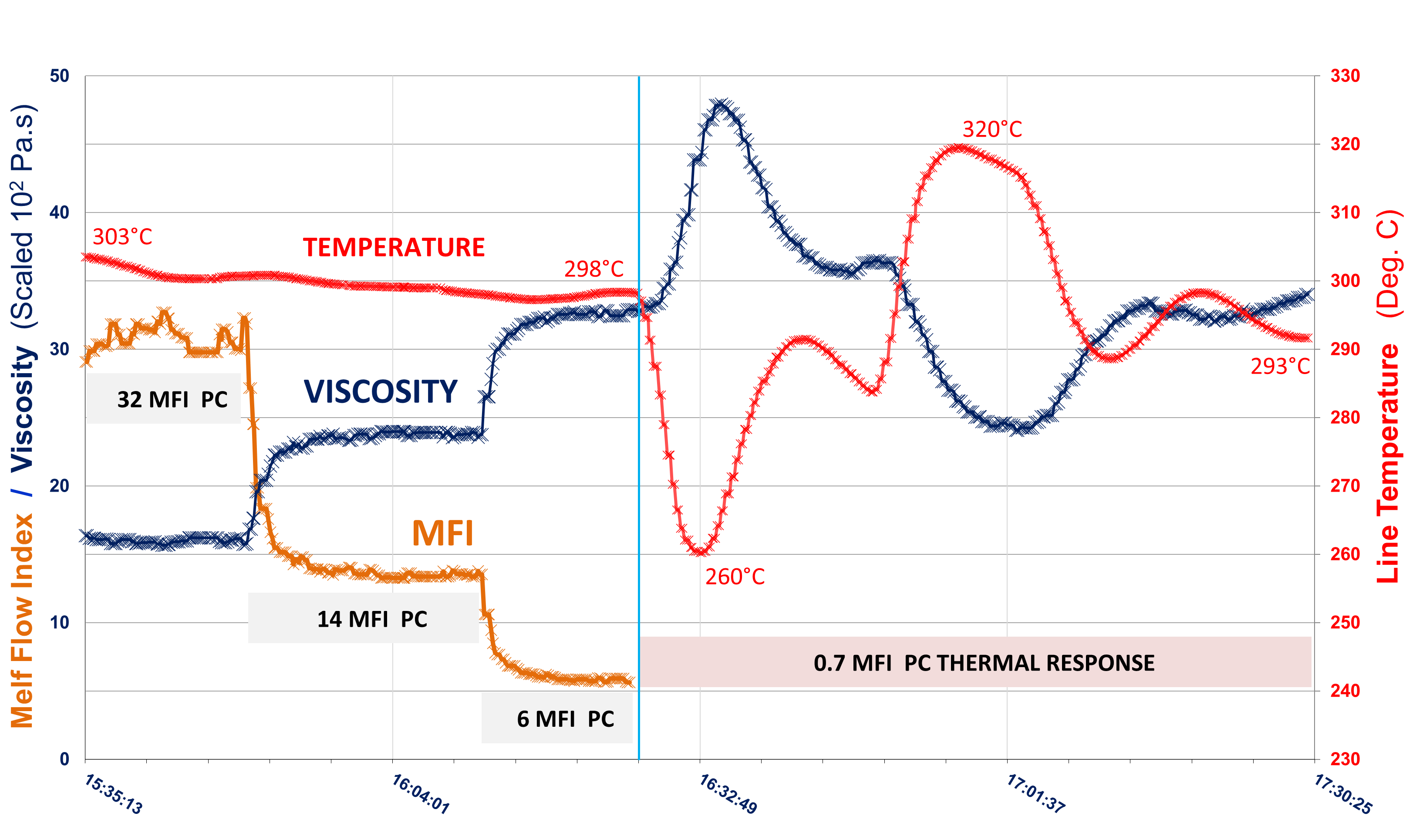

The joy of real-time monitoring…

MFI

Real time ViscoMelt MFI and Viscosity for 3 grades of polycarbonate (PC) under continuous extruder flow with viscosity response under extruder temperature modulation.

IV

Real time ViscoMelt IV for Virgin PET (vPET) and Recycled PET (rPET) under continuous extruder flow.