Don’t let bad IV derail your recycled material quality

Recycling is all about turning waste back into usable materials. But the rheology of the melt can make or break this process. Intrinsic viscosity (IV) is a key indicator of polymer chain length for PET and tells you how well your material will process and perform. If its too high, pellets may form inconsistently. If it’s too low, mechanical properties can be compromised. Without real-time IV control, achieving consistent PET quality and reliable downstream processing can be challenging.

Recycled feedstock is unpredictable

Material sources vary, contamination levels fluctuate, and degradation from previous processing cycles impacts performance. Two batches labeled the same can behave completely differently during extrusion. When blending this feedstock with virgin material, it then creates a major challenge with stability, quality or further downstream operations. A continuous view of IV inside the extruder enables you to respond to varience in the recycled material and optimise the blend ratio.

Speed is of the essence

Waiting for lab results means the response is often too late, leading to waste, rework, or customer complaints. You need to see any change in IV as it happens, directly in the melt stream, so you can react quickly before problems spread downstream. If you’re only catching these problems in the lab, you’re already dealing with out-of-spec material or compromised downstream processing.ViscoMelt gives you realtime IV.

In line. At process conditions. Every few seconds.

From a compact, lightweight sensor that is affordable, deployable and fast.

ViscoMelt is the eyes in the process. It provides critical melt flow data every few seconds with exceptional repeatability. Inline. In the heart of the melt stream. 24/7 melt flow data for lights out control. All from a single device you can hold in your hand. With no moving parts and no maintenance.

You need to get inline. True inline. Not at-line.

No walking back and forth to the lab. No big, expensive, high-maintenance at-line devices. Just a continuous view of melt properties at true processing conditions.The ViscoMelt’s inconel monopole spikes sit directly in the heart of the flow. The beautifully compact design allows melts to flow freely over the sensor surface, with an instantaneous response upon fluid contact. No gear pumps, melt extraction or melt disposal.

Designed to Retrofit

ViscoMelt’s super compact footprint is ideally suited to tight spaces including extruders and narrow bore melt pipes. And its lightweight solid-state design provides easy installation onto standard thread ports.Upgrade a thermometer to a melt viscometer.

It’s that easy.

.png?)

Real time melt data

At your fingertips

One simple device does it all.

Viscosity. MFI. IV. Instant insights, anywhere you need them. Tablet, phone, or integrated system. Stay in control with real-time melt stream analysis.“The Hydramotion viscometer is the largest single improvement we have made in the manufacturing process and it continues to help us keep our products within specification and reduce waste.”

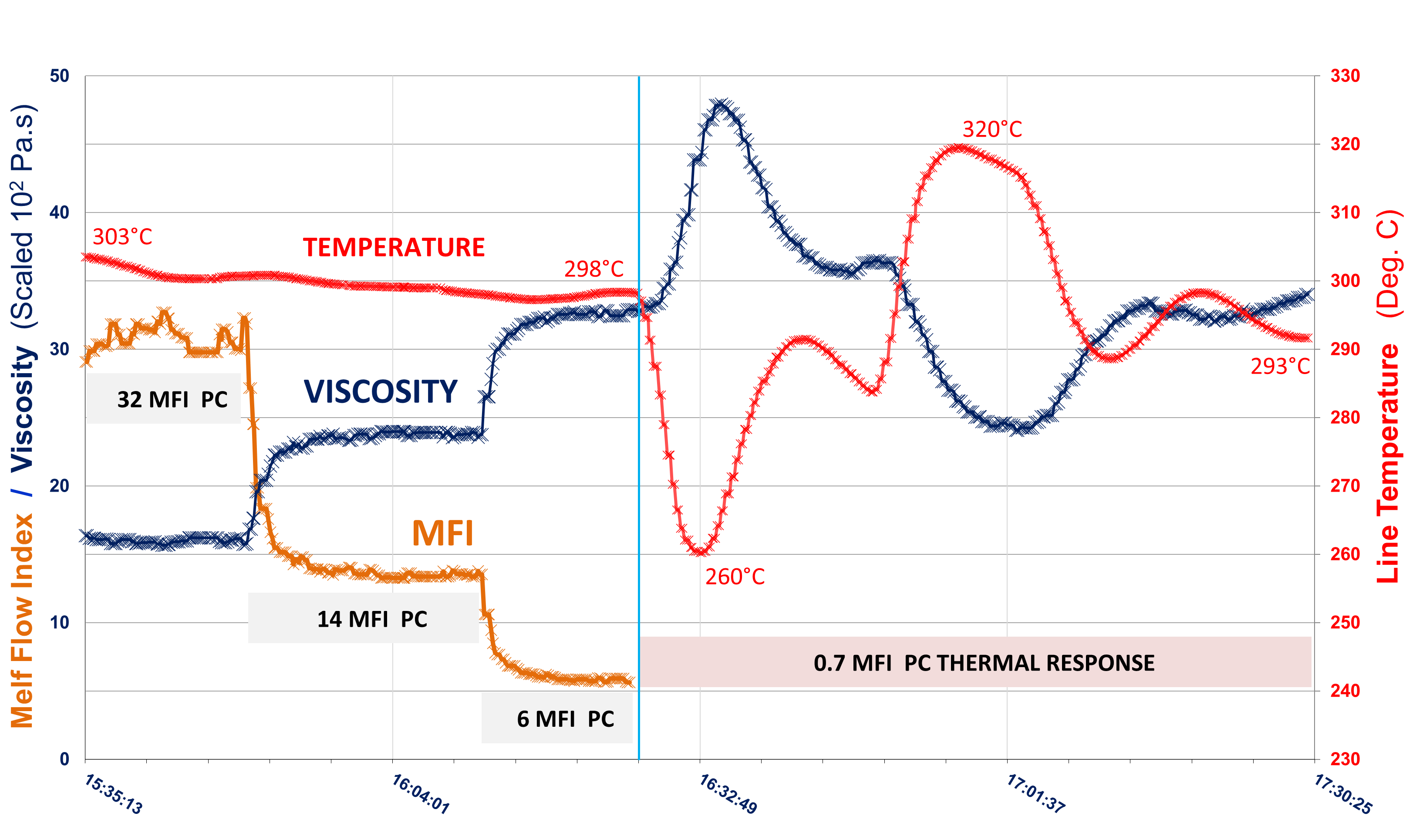

The joy of real-time monitoring…

MFI

Real time ViscoMelt MFI and Viscosity for 3 grades of polycarbonate (PC) under continuous extruder flow with viscosity response under extruder temperature modulation.

IV

Real time ViscoMelt IV for Virgin PET (vPET) and Recycled PET (rPET) under continuous extruder flow.