Scorpion

Scorpion brings lab-level insight for thermoplastics straight to the production line. In ways never before possible.

Developed over a decade of research and innovation, Scorpion combines advanced engineering with a new proprietary measurement technique, designed for the evolving demands of the thermoplastics lifecycle.

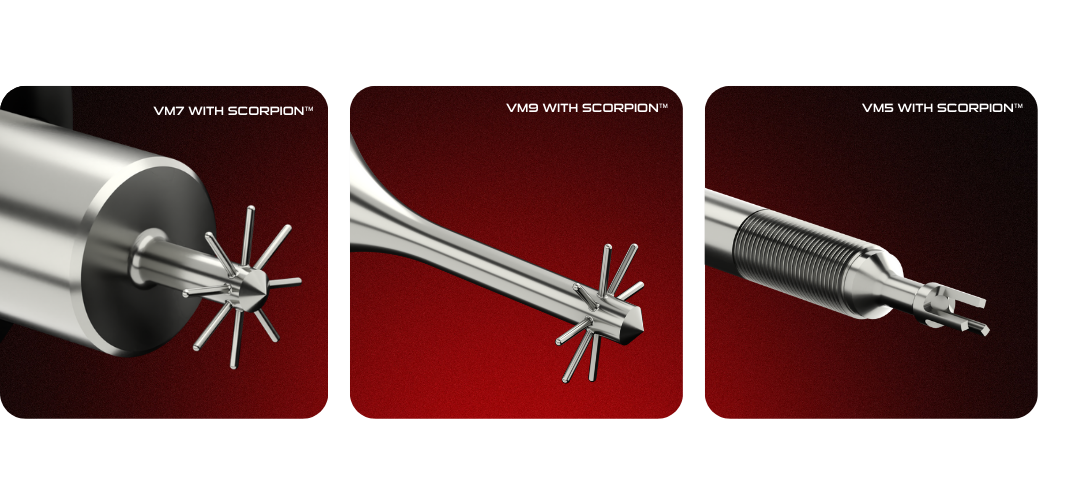

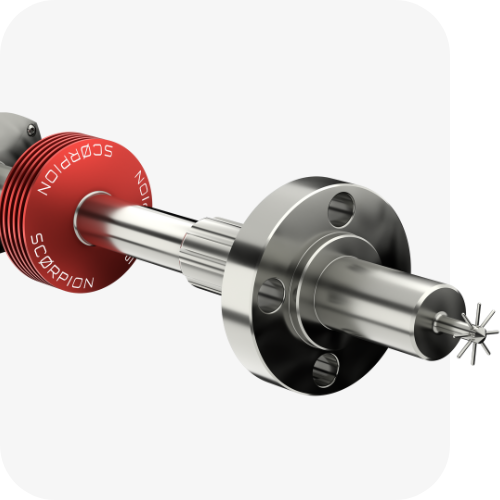

At its heart, a state-of-the-art resonator. At its core, completely new wave mechanics. On the surface, a revolutionary spike architecture. Every element engineered for one thing: to redefine melt flow measurement.

New wave mechanics

The all-new spike architecture along with proprietary new wave mechanics allows the sensor to access both the elastic and viscous components of thermoplastics, in equal measure.

By propagating radial waves into the neighbouring melt and controlling the wave field between the pins and the conventional resonator, a special phenomenon is observed. Revealing the whole viscoelastic picture of the melt.

The Measurement Challenge

The industry has long needed a measurement solution that combines resonant convenience with true MW/complex viscosity capability…

The most important characteristic of any polymer melt is its chain length, or molecular weight, which strongly influences how it flows. That flow behaviour is a function of both its viscosity and elasticity.

For many thermoplastics, the elastic component is often the stronger indicator of molecular weight, especially for longer chain molecules. But picking up the elastic response is dependant on how it responds to shear during measurement.

At very low shear rate, elasticity dominates. And the relationship of complex viscosity with MW is preserved. At higher shear rate, or frequency, elastic effects are diminished, and the relationship begins to break down.

Laboratory techniques such as capillary and rotational rheometers operate at low shear but are slow, high maintenance off-line devices.

Resonant viscometers are by far the most robust and reliable in-line solutions but are fundamentally high shear devices that respond primarily to the viscous component.

The industry has long needed a measurement solution that combines resonant convenience with true MW/complex viscosity capability…

Scørpion™ Solves the Puzzle

A true technological breakthrough that delivers all the benefits of tried and trusted resonant viscometers but with the unique capability of measuring both elasticity and viscosity in real time.

That means laboratory results of viscosity, MFI and IV are taking place at the most testing in-line conditions – the highest flow, temperature and pressures – with readings every 5 seconds.

.png?)

Scørpion™ powering ViscoMelt

Scorpion technology is what powers Hydramotion’s new range of ViscoMelt inline melt sensors. Laboratory-grade data directly in the line. Compiled into a single convenient device that is compact and deployable, with no maintenance.To drive up quality, improve productivity and reduce waste. Right across the value chain. From polymer production, to manufacture, to recycling.