Viscosity sensors for the polymer industry

Polymer processing operates under strict control of melt consistency, molecular weight and thermal stability. Small deviations in rheology can directly affect mechanical properties, surface quality and downstream processing operations. Measurement technology must therefore deliver reliable, reapatable melt data, whilst withstanding the high temperatures, high pressures and demands of the industry.

Hydramotion in-line viscometers are routinely used by the polymer industry across various stages of processing and handling from material production, to manufacture, to recycling.

During material manufacture, viscosity plays a critical role by ensuring the consistency and quality of polymer products due to its correlation with molecular weight. For recycling processess viscosity is critical to how well a recycled blend of material will process and perform.

In the melt pipe or extruder phase, viscosity control becomes crucial for monitoring polymer melts and ensuring that the end-product meets the desired specifications for strength, flexibility, and overall performance.

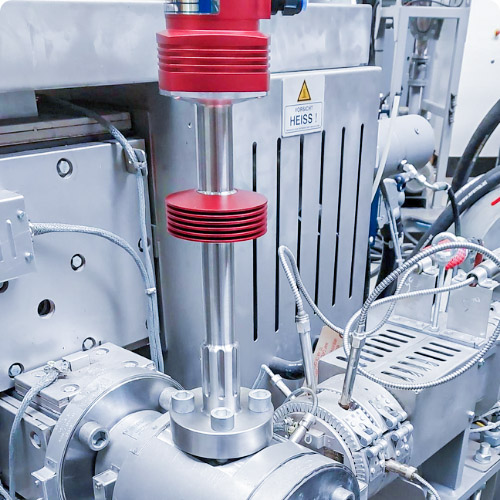

Real-time process controlHydramotion viscometers install directly into melt pipelines, reactors or extruder ports via virtually any standard process connection. Continuous viscosity data can be fed directly into PLC or DCS systems, enabling closed-loop process control to maintain consistent product quality and minimise scrap. |

Chemically resistantGlass-filled, mineral-loaded and pigment-rich formulations present challenging operating conditions. The robust sensor design contains no narrow capillaries or fragile components, allowing reliable viscosity measurement in highly filled or reinforced polymers without blockage or excessive wear. |

.png) High pressure and temperaturePolymer melts are commonly processed at temperatures up to 350°C under significant pressures. All wetted components are made from high-grade alloys capable of sustained thermal exposure, and suitable for direct installation into pressurised pipelines, reactors and extruders. |

APPLICATIONS

.png?x=-0.84375&y=-0.46875&w=504&o=500?)

|

Streamlining PET Flake Recycling with Inline Viscosity Monitoring

Glycolysis is utilised for the chemical depolymerisation of PET to produce polyols. This process involves the addition of glycol to tanks, which is then stirred and heated to high temperatures before the addition of PET flakes….

|

|---|

|

XL7 Optimises Efficiency in Industrial Polyester Yarn (PET) Production

XL7 d16 viscometers are installed directly in melt-pipes to solve a number of process challenges. These include the handling of highly viscous melt, flexible and efficient production of PET, and delivering on ambitious efficiency and emissions targets…

|

|