XL7

Installation

sales@hydramotion.comInstallation

Putting it to work

XL7 viscometers are designed to work right in the heart of the process.

They are not affected by pipe/tank size or upset by gas or air bubbles. Installation and operation is straightforward, and should not require any special training or skills.

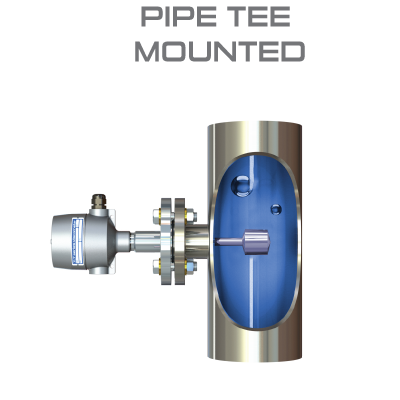

- Mounts on any tank or pipe

- Operates in any orientation

- No special pipework

- No pumps or bypass piping

- Any process connection

- Cable length up to 1000m

- No on-site calibration

- Easy fitting

Viscometer Installation

The XL7 viscometer can be mounted in any orientation and comes with the process connection to suit your needs. Sensors mount on standard pipework – simply hook-up and you’re ready to measure viscosity. And there’s no on-site recalibration work needed either, since perfect calibration is maintained in all conditions.

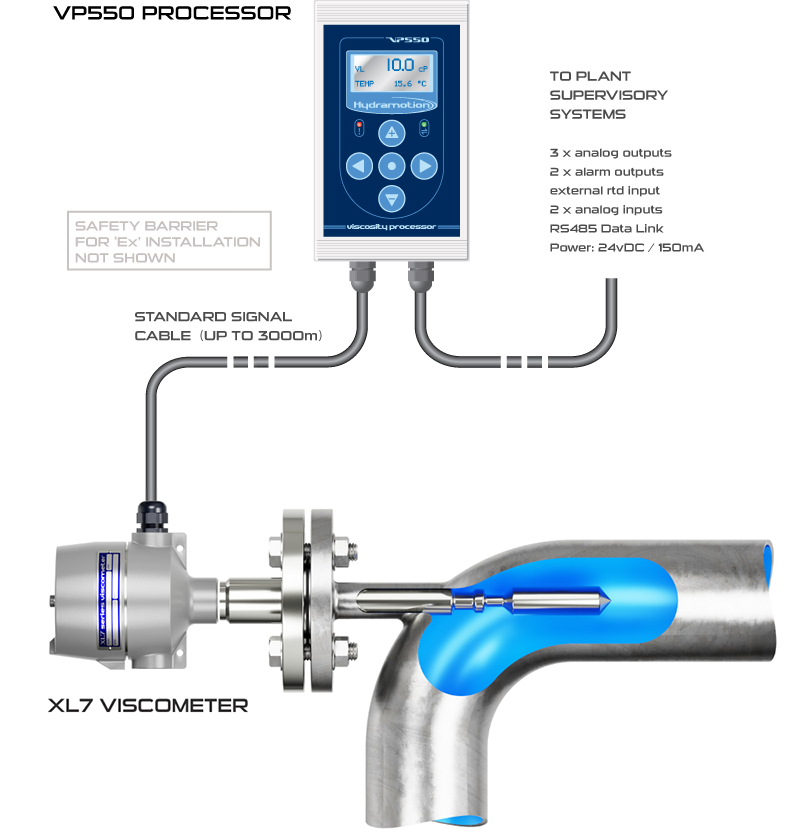

XL7 Hook-up

The VP550 Processor is connected to the XL7 viscometer via a simple 3-core cable and provides all the features for plant operation. Sensor and processor can be mounted up to 1000 metres apart. Analog 4 – 20mA and serial data outputs allow for direct connection to recording and supervisory equipment for viscosity monitoring and control.XL7 viscometers are frequently used as the critical element in an automatic viscosity control loop.