XVisc

Say Hello to XVisc

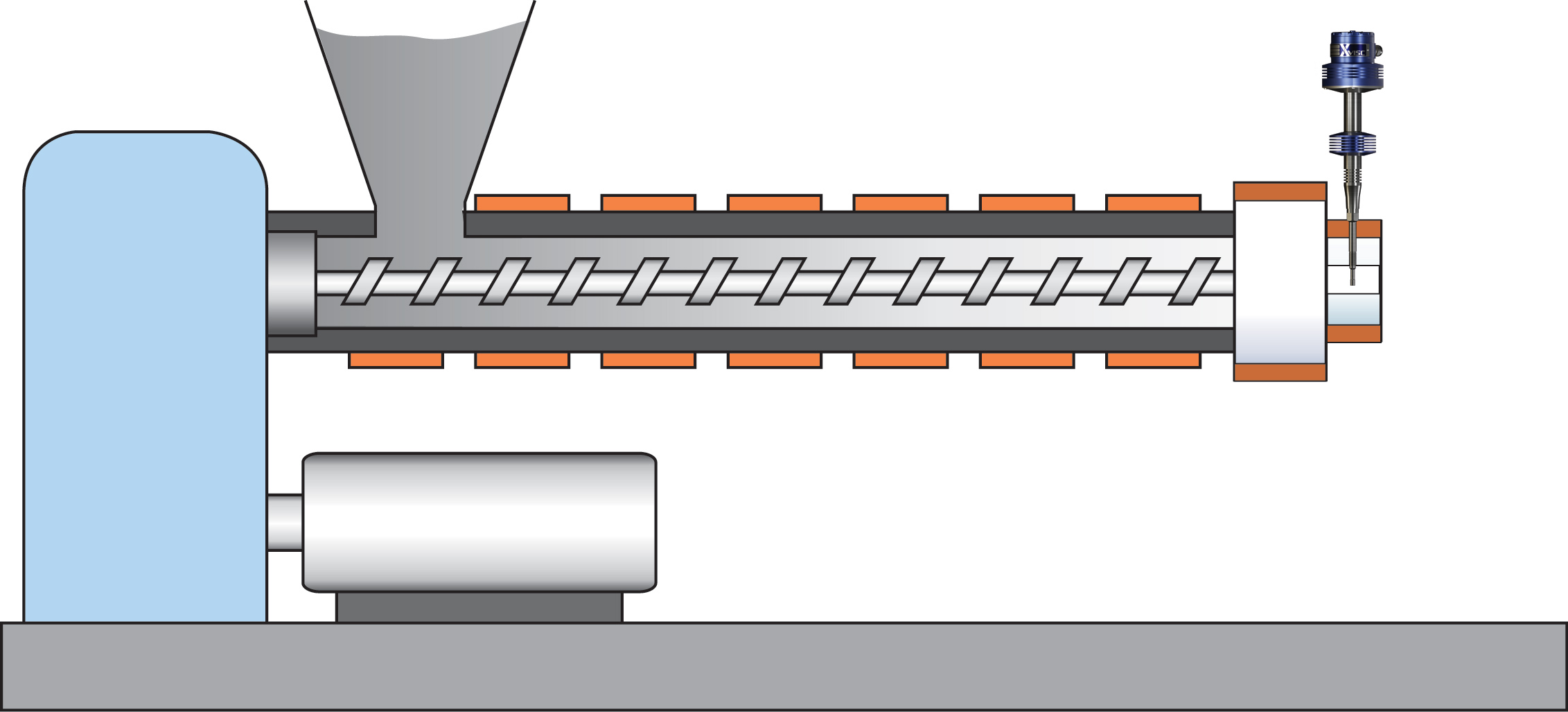

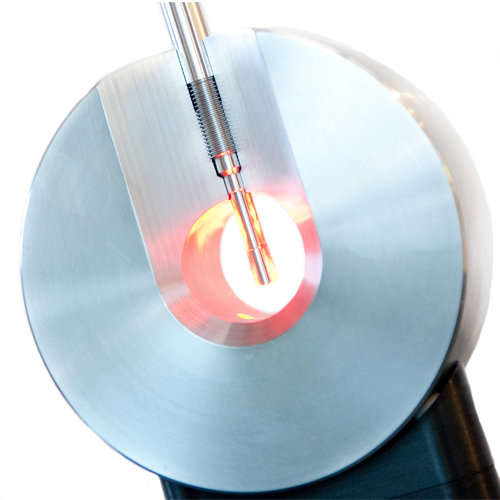

Until now, no instrument has had the capability to accurately measure viscosity of food products inside an extruder. Enter the XVisc. A world first. The beautifully simple solid state sensor delivers you real time viscosity in the heart of the extruder, every second of the day. Your permanent eyes into process.

Welcome to increased product quality, reduced waste and the productivity improvements that

come with real control.

AGAINST THE GRAIN

Hydramotion to the core

Viscosity measurement is critical during extrusion to monitor process efficiency, reduce waste, and improve product quality.The high sensitivity and excellent repeatability of the XVisc allows for continuous insight into the extrusion process and provides real-time production control.

Hit the Sweet Spot

PERFECT PRODUCT EVERY TIME

The purpose is to eliminate sampling, improve product consistency, and to optimise the extrusion process. No half measures. No compromises.

It’s about finding the sweet spot. Too early means misshapen products, too late means wasted food. The XVisc finds that critical point, for a perfect product every time.

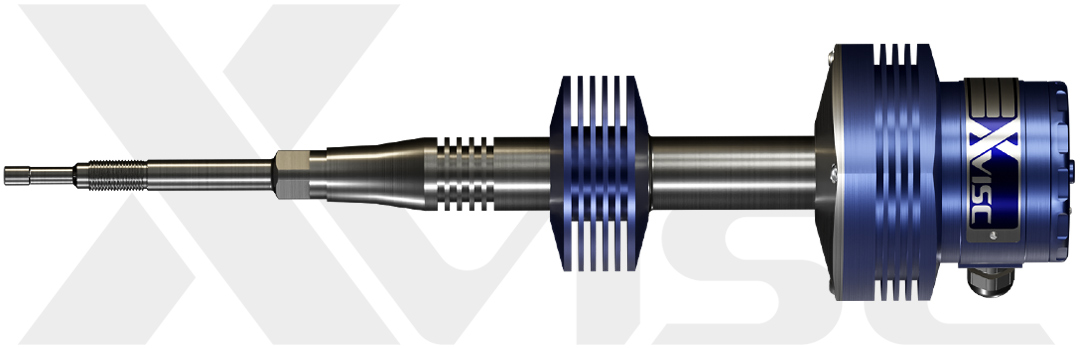

Simplicity Is Its Success

BUILT AROUND YOUR EXTRUDER

Seamless integration into your existing extruder. It’s never been easier. XVisc can be installed directly in the flow without the need for additional pipework.With its standard 1/2” UNF thread, installation is simple. Either utilise a spare port or replace a thermometer and fit to the barrel or die. Connect to the power and you are ready to go.

And with XVisc’s inbuilt thermometer, there’s no sacrifice to functionality.

Eyes in the Extruder

Shaping Your Process

Viscosity provides a window into material changes such as starch gelatinisation or changes to protein and fibre structure. Revolutionise your food extrusion process by gaining valuable information about these key parameters.

This insight can also inform your process design in areas such as screw flow dynamics, screw energy consumptions, and die pressure drop.

Viscosity Is Knowledge

We understand that knowledge is power. Our no compromise design ethos is testament to that. We put everything we know about viscosity measurement into the XVisc to provide you with the knowledge, the power and the insight to transform your process.

Smart. Beautiful. XVISC.