Viscojet

The Standalone Process Viscometer

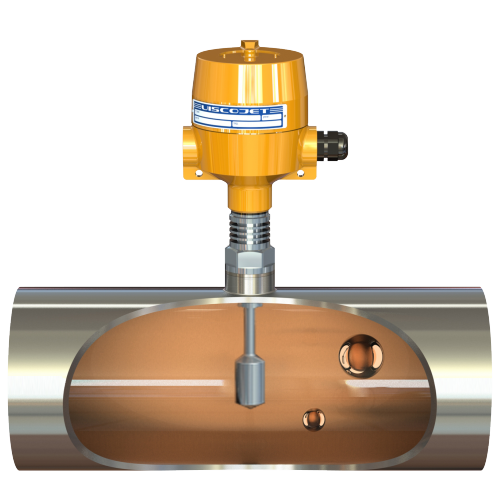

ViscoJet is a high-performance stand-alone viscometer which measures viscosity every second with high sensitivity and excellent repeatability. The integral thermometer provides simultaneous measurement of fluid temperature, allowing calculation of viscosity corrected to a reference temperature. All the necessary functions to derive real-time viscosity are performed by the sensor and its integral electronics.

Available from stock and ready to use in any location, ViscoJet is fully calibrated and requires no on-site adjustments.

A Vital Component

No other viscometer has it all

- High accuracy

- Inserts directly into flow – no shields

- Fits any pipe or tank

- Easy installation – standard cables

- No routine maintenance

- Not affected by flow, bubbles or solids

- Standalone operation

- Low cost

- Fast delivery

- Lloyd’s register type approval

Standalone

all in the head

With its two built-in 4-20mA outputs and digital data bus the ViscoJet is a completely self-contained solution.

The analogue outputs represent line viscosity and temperature and are updated every second. The sensor can be used on its own or connected to any Hydramotion VP processor, or direct to DCS system.

Simple installation, standard cabling, and standalone sensor operation means less cost and easy setup. Viscosity at its leanest.

3 Daily Profit Drivers

Increase QualityAchieve end-product quality by tracking process change in real-time and proactively take action. |

Eliminate WasteInstantly detect off-spec product or process drift and adjust the process in real-time to bring the material back into spec. |

Transform ProductivityAutomate your viscosity measurement and control and reduce reliance on manual offline measurements. |

ALL FLUIDS

ALL CONDITIONS

Nothing troubles ViscoJet.

The high strength sensor is always in full contact with the fluid and measures viscosity to the exclusion of everything else. There are no vulnerable parts or shrouds to foul or get in the way.

A hybrid of robustness and high precision that can track the tiniest changes in viscosity.

Simply connect to the line and you’ve got viscosity and temperature you can rely on.

Use Freely

Any Pipe. Any Tank. No Guards

Having both high viscosity sensitivity and immunity to everything else – flow, plant noise and vibration, temperature, pressure, gas bubbles – makes the ViscoJet special.

The viscometer does not require any specific spool pieces or pipework, so it can be used freely anywhere in the system. Nor are there any guards or shields to obstruct the measurement.

The ViscoJet just sits at the centre of the pipe, fully exposed to the flow and perfectly positioned for optimum fluid management.

Resonant Technology

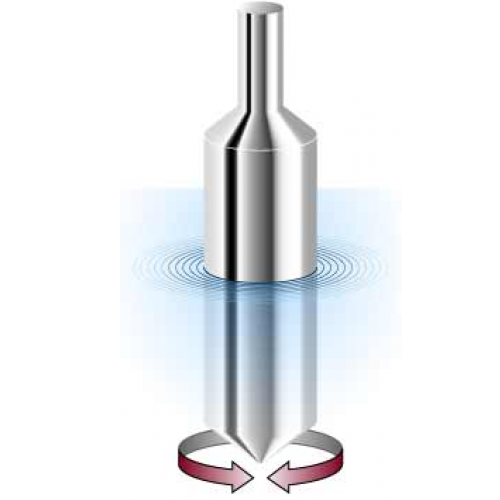

At the heart of the ViscoJet is our proven resonant technology, used in thousands of Hydramotion viscometers worldwide.

Each ViscoJet features a solid state sensor which is both tough and sensitive. It is able to detect the smallest change in fuel viscosity whilst giving long unattended service. There are no moving parts to replace or service, along with the unwelcome downtime. Consequently maintenance is negligible and cost of ownership unbeatably low.