Viscojet

Viscojet Works

Out of the Box

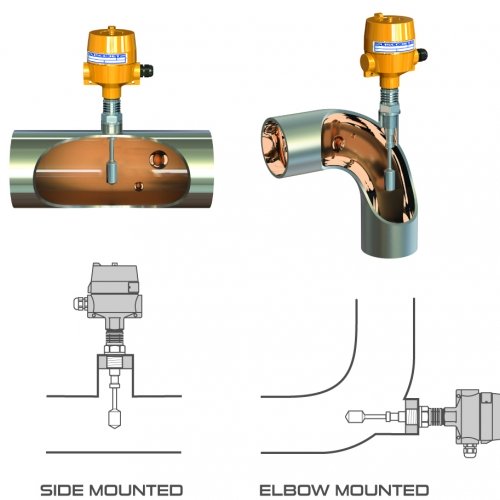

Installation and operation is straightforward

and should not require any special training or skills.

- Mounts on any tank or pipe

- Operates in any orientation

- No special pipework

- No pumps or bypass piping

- Any process connection

- Cable length up to 1000m

- No on-site calibration

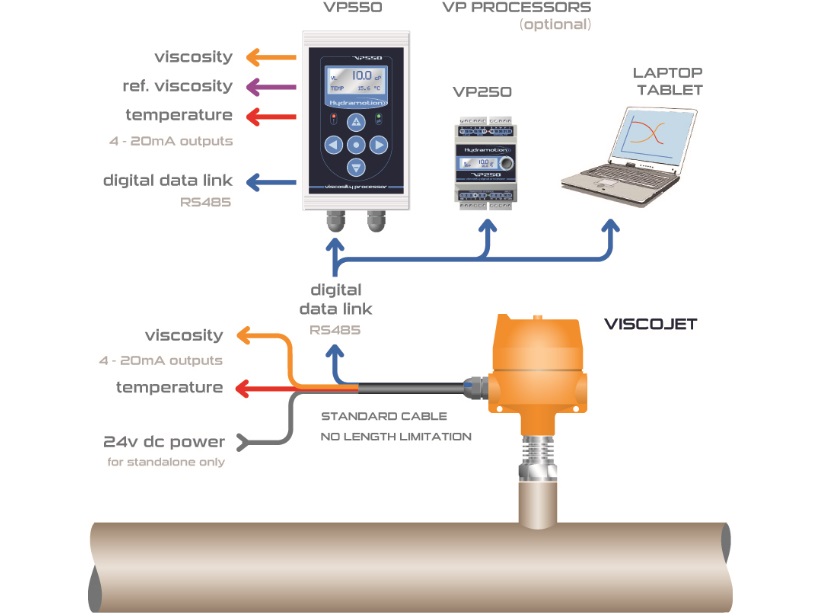

ViscoJet Hook-Up

VP Processors provide a local display and an array of useful outputs for recording or control.

The ViscoJet can also be directly connected to a PC, laptop or tablet for continuous or occasional viscosity monitoring, as well as user configuration of the various sensor functions.

VP Processor Connection

The ViscoJet sensor and VP550 Processor may be linked by standard 3-core signal cable over a distance of up to 1000 meters. Analogue 4 – 20mA and RS485 digital data outputs from either the ViscoJet or the VP550 can be connected directly to recording and supervisory equipment for viscosity monitoring and control.

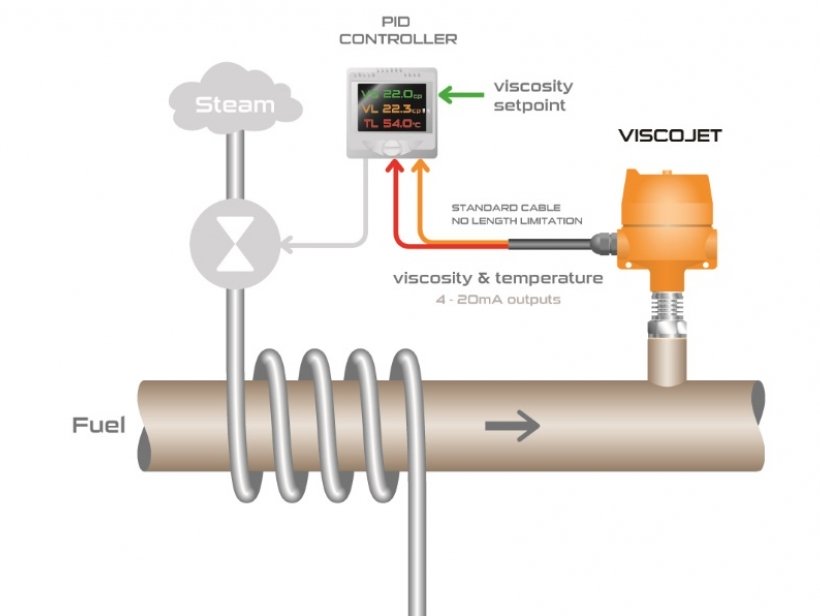

Closing the Loop

For marine and fuel oil applications, a simple control loop is achieved with a ViscoJet and PID controller.